Actuators exist in different forms, and the most versatile are the electric ones. As the name suggests, the devices employ electric currents to create motion. They’re of two types: linear and rotary. The most common among both is the former due to efficiency.

Besides efficiency, linear electric actuators are also versatile. As a result, they play roles in different industries and applications. Here, however, our interest is in automobiles.

Almost every modern car today features one electric actuator or the other. Why? Well, it’s because they bring in many benefits based on how they function. Read on as we elaborate on this.

How Electric Actuators Work

Simply put, electric actuators convert electrical energy into mechanical motion. They come with an electric motor that creates movement from the converted energy. This motor will feature a screw or rod if it generates linear motion. If it’s rotary, then it’ll come with a shaft or table.

To start operating, electric actuators depend on signals from a control device. This controller is usually a sensor or the car’s electric module.

Note that the signal the electric actuator receives is usually low voltage because it doesn’t power the device. What powers the actuator motor is the car battery. This is why most will fail to function or perform poorly if the car battery is down.

Furthermore, for the device to work optimally, it must carry an appropriate load, matching the motor’s speed, torque, and force. So, if you use the device for higher demands than it’s cut out, it’ll break down. To avoid this, visit this website to find electric linear actuators for various applications.

Main Components of Electric Actuators

To fully grasp how electric actuators work in cars, you should know the different components. Check them out below:

The main components of electric actuators in cars are:

1. Motor

As mentioned earlier, the electric actuator motor handles the conversion from electrical energy to mechanical motion. A linear motion will complete this task by sliding a screw or rod. Meanwhile, a rotary one works by sobbing a shaft or table.

2. Controller

Electric actuators in cars need a signal to know when to start working. That signal comes from the controller, which, as stated already, can be a sensor or the car’s module. Another function of the controller is to get feedback from the motor. That way, the actuator can adjust to accommodate the position, speed, and force requirements to keep the car running optimally.

3. Load

A car electric actuator can be applied to brakes or steering. It can also be installed in doors and windows or the transmission and suspension. Each of these applications requires different capacities, depending on the load. Hence, the load works hand in hand with the motor and controller to pass feedback and provide resistance when needed.

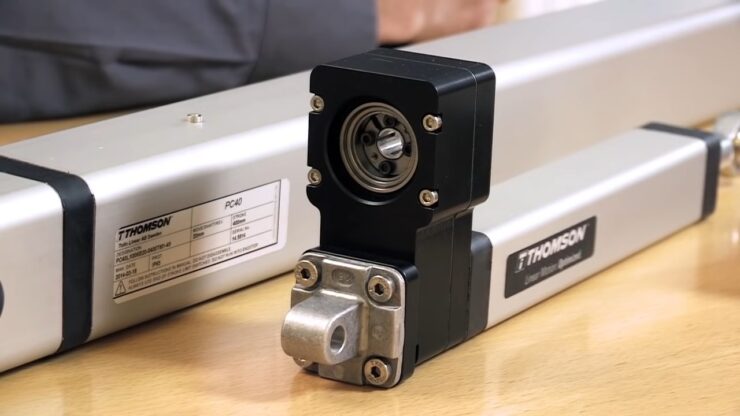

4. Gearbox or Screw

The gearbox or screw forms an integral part of the load. Mainly, this component ensures the speed and force coming from the motor satisfy the load requirements. Thus, it helps avoid problems if the load is unbalanced. Note that the gearbox is the most common. You’ll only find screws in electric actuators that convert rotary motion into linear motion. Such devices aren’t popular in cars.

Electric Actuator Operations In Car Systems

Having understood how electric actuators work and their components, here are some typical applications of these devices in car systems:

1. The Car Engine

Electric actuators dictate the air and fuel quantity that goes into the engine. In addition, the motion devices are responsible for redistributing exhaust gas and valve timing. With all this, it’s clear that electric actuators significantly affect engine performance. Not just that, but also emissions and fuel efficiency.

2. The Transmission System

Finding a modern card without electric actuators in its clutches and gear shift units is hard. That’s how penetrative these motion devices are regarding automobile transmission. They apply to not only electric transmissions but also automatic, manual, and hybrid. Consequently, they influence the car’s speed, torque, and power.

3. Climate Control System

As you ride in your car, you enjoy the cool air from the AC when it’s hot. Likewise, when it is cold, you switch on the heater to keep the interior warm. All these are made efficient thanks to electric linear actuators. These devices control the flaps, vents, heaters, and fans that determine your vehicle’s climate.

4. Vehicle Safety System

Electric actuators further help improve car safety. They do this by optimising critical systems like braking, steering, and suspension. In particular, they ensure you apply the proper force and pressure to operate the mentioned components. The result is a more stable and better-handled automobile.

What Are the Benefits of Electric Actuators In Cars

It’s not wrong to say electric actuators bring endless benefits to car users. Indeed, it would take time to enumerate all the advantages. Nevertheless, check out the top ones below:

- Better Efficiency: thanks to their application in engine, transmission, and braking, electric actuators can facilitate optimal operations. For instance, they can reduce the litres of fuel the car consumes and the kilograms of emissions it releases. But that’s not all. Since electric actuators are more minimalistic than their hydraulic and pneumatic counterparts, they tend to reduce the car’s weight.

- Better Accuracy: Electric actuators will ensure different car components get the right amount of force and torque to operate. But, more importantly, they ensure the parts are correctly positioned. That equals higher accuracy, eliminating under or over-performance, which can promote wear and tear.

- Better Dependability: you can worry less about events like overheating and overloading with an electric actuator in your car. As mentioned, these motion devices differ from the hydraulic and pneumatic types. Typically, they come with cooling systems and protection circuits, making them dependable for long periods.

Conclusion

Cars feature electric actuators for various functions, and the motion devices work with different systems. The engine, transmission, climate control, and safety systems discussed in this post are only a few — there are many more. However, every application has one end goal: to make the vehicle run faster and safer. So far, electric actuators have proven to be highly dependable in car operations, and, as a result, automobile manufacturers will continue leveraging them.