A torque wrench is a specialized tool designed to apply a specific amount of torque to a fastener. It is commonly used in automotive and industrial settings to ensure that bolts are tightened to the manufacturer’s specifications.

They are available in different types, including beam, click, and digital. They are designed to measure torque and are not designed to be used as a general-purpose tool.

Can You Use A Torque Wrench As A Breaker Bar?

Using a torque wrench as a breaker bar can potentially damage the wrench and make it less accurate over time. Torque wrenches are designed with internal mechanisms that allow them to measure and apply a specific amount of torque. If a torque wrench is used as a breaker bar, the internal mechanism could be damaged, resulting in inaccurate torque measurements and potentially causing damage to the bolt or surrounding components.

Additionally, torque wrenches are not designed to withstand the high levels of force that a breaker bar can produce. Applying excessive force to a torque wrench can cause it to break or become permanently damaged, rendering it unusable.

If you need a tool to loosen tight bolts or nuts, it is best to use a breaker bar or a socket wrench with a cheater bar. A breaker bar is designed specifically for this purpose and can provide the extra leverage needed to loosen tight bolts or nuts without damaging the tool or surrounding components.

The Differences

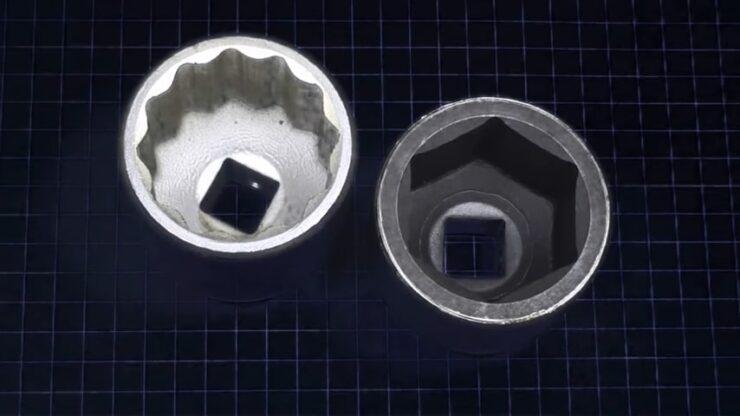

Two common tools that are often used are torque wrenches and breaker bars. While both of these tools can be used to tighten or loosen nuts and bolts, they have different designs and purposes.

A torque wrench is a tool that is designed to apply a specific amount of torque or force to a bolt or nut. This is important for ensuring that the bolt is tightened to the correct specification, which is crucial for safety and to avoid damaging the bolt or the surrounding components. They come in a variety of types, including click-type, beam-type, and digital torque wrenches.

Click-type torque wrenches are perhaps the most common type and are designed to produce an audible click when the desired torque is reached. Beam-type torque wrenches use a beam that flexes under tension to indicate the amount of torque being applied. Digital torque wrenches have a digital display that shows the amount of torque being applied.

Breaker bars, on the other hand, are designed to provide extra leverage to loosen tight bolts. They are typically longer than torque wrenches and have a square drive on one end that fits into a socket. When using a breaker bar, the user can apply more force to the nut or bolt than they would be able to with a regular wrench, making it easier to loosen bolts or nuts that are particularly tight or difficult to remove.

One of the key differences between them is their accuracy. Torque wrenches are designed to be very accurate in terms of the amount of torque they apply. They are often calibrated and have a specific range that they can apply.

This is important for applications where the bolt needs to be tightened to a specific level of tightness, such as in automotive or aerospace applications. Breaker bars, on the other hand, do not have any mechanism for measuring the amount of force being applied, so they are not accurate in this sense.

In terms of usage, torque wrenches are typically used when tightening bolts or nuts to a specific torque specification. This is important for applications where it is crucial that the bolt or nut is tightened to a specific level of tightness.

Breaker bars, on the other hand, are typically used when loosening bolts or nuts that are particularly tight or difficult to remove. For example, a breaker bar might be used to loosen the lug nuts on a car wheel before using a torque wrench to tighten them to the correct specification.

How Does a Torque Wrench Work?

A torque wrench is a precision tool used to apply a specific amount of torque or twisting force to a bolt or nut. Torque is a measure of the force applied to an object that causes it to rotate around an axis. They are commonly used in automotive, mechanical, and industrial applications to ensure that bolts are tightened to the correct specification.

The basic design of it consists of a handle, a shaft, and a head. The head of the wrench holds the socket or other attachment that fits onto the bolt or nut being tightened. The shaft of the wrench contains a torsion bar or other mechanism that resists twisting when force is applied to the wrench. The handle of the wrench is used to apply the force.

When using a torque wrench, the user sets the desired amount of torque using a scale or digital readout on the wrench. This scale or readout is typically measured in units of foot-pounds or Newton-meters, depending on the application. Once the desired torque has been set, the user tightens the bolt or nut using the wrench until the desired torque is reached.

The mechanism inside it works by compressing or stretching a torsion bar or other element inside the shaft of the wrench. As the user applies force to the handle of the wrench, the torsion bar or element resists twisting until the desired amount of torque is reached.

At this point, the wrench may produce an audible click, or a digital readout may indicate that the desired torque has been achieved.

There are several types available, including click-type, beam-type, and digital torque wrenches. Click-type torque wrenches are perhaps the most common type and are designed to produce an audible click when the desired torque is reached. Beam-type torque wrenches use a beam that flexes under tension to indicate the amount of torque being applied.

Digital ones have a digital display that shows the amount of torque being applied.

How Does a Breaker Bar Work?

A breaker bar is a tool used to provide extra leverage when loosening tight bolts or nuts. The tool consists of a long handle attached to a square drive head that accepts sockets of various sizes. Breaker bars are commonly used in automotive, mechanical, and industrial applications to loosen stubborn bolts or nuts that cannot be easily removed with a standard socket wrench.

The design is relatively simple. The long handle provides additional leverage, which allows the user to apply more force to the bolt or nut being loosened. This increased force can help break loose rusted or seized fasteners that would be difficult or impossible to remove with a standard socket wrench.

When using a breaker bar, the user fits the appropriate socket onto the square drive head and places it over the bolt or nut being loosened. The user then applies force to the handle of the breaker bar, which translates into torque on the bolt or nut.

Because the handle of the breaker bar is longer than that of a standard socket wrench, the user is able to apply more force and torque to the bolt or nut, making it easier to break it loose.

They come in various sizes and lengths to accommodate different applications. The length of the handle is typically the most important factor in determining the amount of leverage that can be applied. Longer handles provide more leverage and are more effective at loosening stubborn bolts or nuts, but they can also be more difficult to use in tight spaces.

In addition to providing extra leverage, breaker bars can also be used with a cheater bar to further increase the amount of force that can be applied. A cheater bar is simply a pipe or other sturdy object that is slipped over the handle of the breaker bar to increase its length and leverage.

What Can You Use Aside From Torque Wrench?

Pump Wrench

For those difficult-to-reach bolts and nuts, pipe wrenches can be utilized. They have a long handle that makes it possible to apply pressure to the right part of the bolt or nut without stripping them out or harming nearby components.

Plug Wrench

For those difficult-to-reach bolts and nuts, another excellent solution is to use socket wrenches. Sockets come in a variety of sizes, from tiny ones designed exclusively for screws to enormous ones used on impact guns that can easily remove even the most obstinate nuts from wheels.

Crowbar

Another tool that can be used as a breaker bar is a crowbar. Crowbars come in a variety of sizes, from large to little. When employing a crowbar instead of a torque wrench and breaker bar setup, the bigger the crowbar, the more force you can exert.

The list of breaker bar options can go on and on. The best advice is to look at your toolbox what you’ve got that could work for this job, then give it a shot!

FAQs

What should you not do with a torque wrench?

You should never put a pipe or any other kind of extension onto a torque wrench handle, as doing so can seriously damage the tool and make it inaccurate. Additionally, you should not use a torque wrench to make the threads initially catch, as it provides a lot of power and, if your nut or bolt isn’t properly tightened, it could be applying more or less torque than you intended to.

What are some rules of torque wrenches?

- Always make sure the torque wrench is properly calibrated before use.

- Never use it with missing or expired certificate of calibration.

- Always pull, DO NOT PUSH, to apply torque and adjust your stance to prevent a fall.

- Never use a “cheater bar” on a torque wrench to apply excess torque.

Do torque wrenches lose accuracy?

Yes, torque wrenches can lose accuracy over time or with improper use.

Conclusion

While a torque wrench and a breaker bar may look similar, they are designed for different purposes and should not be used interchangeably. If you need to loosen tight bolts or nuts, it is best to use a breaker bar or a socket wrench with a cheater bar rather than risking damage to your torque wrench.